We have all experienced it. You visit your physician and hear the words, “We need to have some labs run.” A laboratory requisition form is printed out and you are instructed where to go to get blood or other specimens collected. You may even have to get a biopsy done. Sometimes the list of tests that need to be run can be mind-boggeling! Have you ever wondered how the blood, urine, nasal swab, biopsy or other items you “donate” make it to the right place for testing? After all, some of your blood may end up in clinical chemistry, some in microbiology, others may end up in molecular testing and your biopsy in anatomic pathology. While most tests are performed in the pathology laboratories at Michigan Medicine, some of the less common tests are sent out to large reference laboratories across the United States. Last year, 7.2 million billable tests were run in our Michigan Medicine laboratories. How are all those specimens routed to the right place? The Department of Pathology has a group of heroes who make this magic happen. They are called the Specimen Processing team.

Once your specimens have been collected, they are walked, mailed, or driven to Michigan Medicine University Hospital where they are delivered to the specimen processing unit. Each specimen bears a bar-coded label and a member of the team scans it into our system. This tracks the location of your specimen and links it to the test requisition. Some specimens may arrive without this bar-coded label accompanied by a requisition form. In this event, the specimen needs to be logged into our system, a bar-coded label is then printed and the specimen becomes trackable for the remainder of its journey through Michigan Medicine.

Once your specimens have been collected, they are walked, mailed, or driven to Michigan Medicine University Hospital where they are delivered to the specimen processing unit. Each specimen bears a bar-coded label and a member of the team scans it into our system. This tracks the location of your specimen and links it to the test requisition. Some specimens may arrive without this bar-coded label accompanied by a requisition form. In this event, the specimen needs to be logged into our system, a bar-coded label is then printed and the specimen becomes trackable for the remainder of its journey through Michigan Medicine.

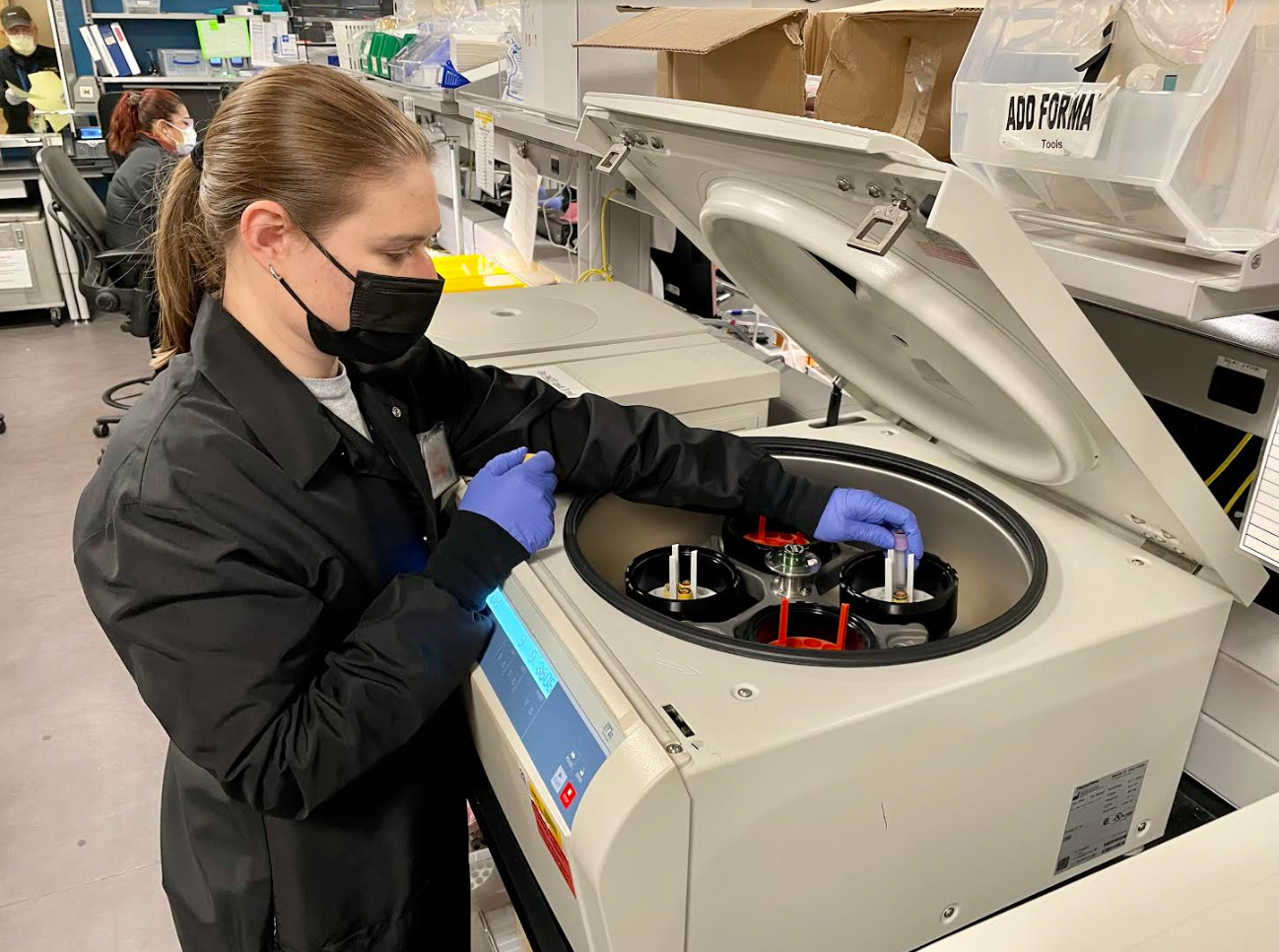

As your specimen is being processed, the specimen processing team is checking to be sure that the right specimen has been received for the test(s) requested. Blood may arrive in several different tubes each bearing different colored tops. These tops are color coded to the types of tests that can be run from the sample. Some tests require the blood to be pure, without any additives, while other tests need specific additives in the tube, such as heparin to prevent clotting. Some tests need whole blood while others need the blood spun down and separated into plasma and whole cells. Specimen processors make sure that the test ordered and the type of specimen received is a match. If they are not, the physician’s office is called and the issue is discussed prior to proceeding.

Once the specimens have been reconciled to the ordered tests, the specimen processors may need to divide the specimens for multiple types of tests going to different areas of the laboratory. This is a process called aliquoting. Specific volumes of the sample are added to new containers for testing. Each of these containers are labeled with a bar-coded label. In many cases, a portion of the sample will be frozen in case repeat testing is needed, or as often happens with our inpatients, a physician requests additional tests be run. This saves patients from getting another poke.

Tissue samples that come from surgeries or skin scrapings are sent to laboratory technicians who embed the tissue in paraffin wax blocks. These tissues are then run through a microtome, which makes very thin slices of the wax and tissue for placement on glass slides and viewing by pathologists under the microscope.

Our specimen processing team then ensures each of the specimens are sent to the right laboratories for testing. These laboratories may be located at University Hospital, in the pathology laboratories at the North Campus Research Complex, or they may be at another institution if we do not process that particular test in-house. These are called “send-outs” and we have a team of specimen processors whose job is to ensure these send-outs are quickly and efficiently processed and delivered to the appropriate laboratory.

The Department of Pathology currently has 61 specimen processors who handle about 21,000 cases daily. Our case volumes continue to grow at an average of 4% annually. This led to a need for more space for specimen processing and testing, which in turn led to the renovations of our core laboratories. For the past couple of years, the specimen processing unit has been in the middle of this renovation project which has necessitated the team be divided and relocated multiple times as their new space is designed and completed. Lean facility design and ongoing quality improvement projects are being utilized to ensure workflows are ideal and systems are designed to reduce or eliminate errors and allow for future expansion.

In spite of the very important and essential functions they perform, no specific education or experience is required for those interested in this position. On-the-job training is provided. According to Michael Fracassi, one of our specimen processors, “The department trained me for a full five months at various stations before I moved to my permanent shift.” He added that computer knowledge is essential and that an understanding of medical terminology would be helpful for someone interested in the position.

Lab Technician Liz Feldcamp stated, “I was originally hired as a Specimen Processor, but once I settled into that position, I realized there was so much more that I could do for the lab. I found that pushing myself to learn all the benches would make me better at my job and be a better asset to those around me. It also helped me achieve my current position now, as a lab technician. You come into SP as a specimen processor and then work your way to becoming a lab tech like a lot of us do, or you can find yourself in management. One of the coolest things about working in SP is that it gives you the ability to interact with all the other core labs which can help you see where your interests lie.”

Lab Technician Liz Feldcamp stated, “I was originally hired as a Specimen Processor, but once I settled into that position, I realized there was so much more that I could do for the lab. I found that pushing myself to learn all the benches would make me better at my job and be a better asset to those around me. It also helped me achieve my current position now, as a lab technician. You come into SP as a specimen processor and then work your way to becoming a lab tech like a lot of us do, or you can find yourself in management. One of the coolest things about working in SP is that it gives you the ability to interact with all the other core labs which can help you see where your interests lie.”

“The problem-solving part of the job is the best part of the job,” reflected Michele Merkel. “Knowing that you can solve an issue, a patient can get their specimen processed appropriately and receive the best care in a timely fashion, is my favorite part of the job. I also like that I don’t have to take the job home with me. I know that when my shift has ended, I can trust my co-workers will provide the best possible patient care, just as I have on the previous shift.”

Specimen Processing is a fascinating position with upward potential…and frequent openings due to case volume growth and upward mobility for staff. If you are interested in a position with Michigan Medicine Department of Pathology as a specimen processor, visit our careers website, and search for Specimen Processor. Your future career awaits you!

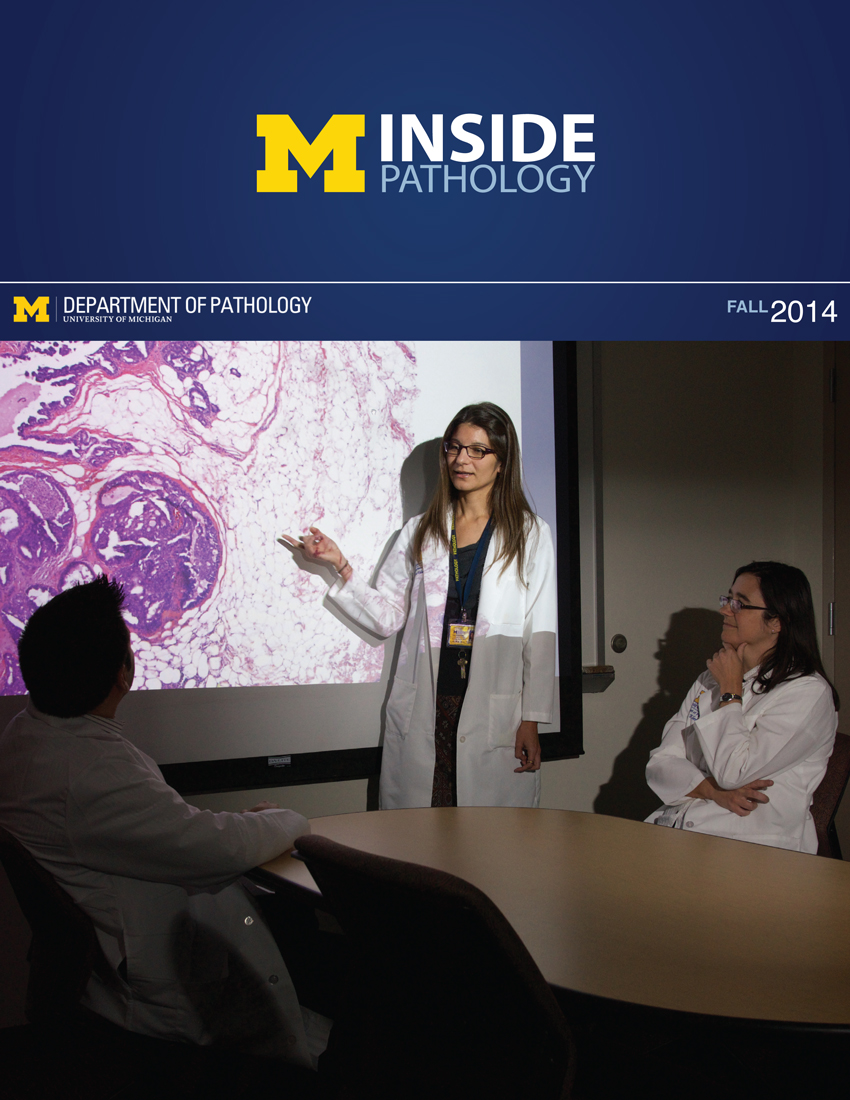

ON THE COVER

ON THE COVER

Breast team reviewing a patient's slide. (From left to right) Ghassan Allo, Fellow; Laura Walters, Clinical Lecturer; Celina Kleer, Professor. See Article 2014Department Chair |

newsletter

INSIDE PATHOLOGYAbout Our NewsletterInside Pathology is an newsletter published by the Chairman's Office to bring news and updates from inside the department's research and to become familiar with those leading it. It is our hope that those who read it will enjoy hearing about those new and familiar, and perhaps help in furthering our research. CONTENTS

|

ON THE COVER

ON THE COVER

Autopsy Technician draws blood while working in the Wayne County morgue. See Article 2016Department Chair |

newsletter

INSIDE PATHOLOGYAbout Our NewsletterInside Pathology is an newsletter published by the Chairman's Office to bring news and updates from inside the department's research and to become familiar with those leading it. It is our hope that those who read it will enjoy hearing about those new and familiar, and perhaps help in furthering our research. CONTENTS

|

ON THE COVER

ON THE COVER

Dr. Sriram Venneti, MD, PhD and Postdoctoral Fellow, Chan Chung, PhD investigate pediatric brain cancer. See Article 2017Department Chair |

newsletter

INSIDE PATHOLOGYAbout Our NewsletterInside Pathology is an newsletter published by the Chairman's Office to bring news and updates from inside the department's research and to become familiar with those leading it. It is our hope that those who read it will enjoy hearing about those new and familiar, and perhaps help in furthering our research. CONTENTS

|

ON THE COVER

ON THE COVER

Director of the Neuropathology Fellowship, Dr. Sandra Camelo-Piragua serves on the Patient and Family Advisory Council. 2018Department Chair |

newsletter

INSIDE PATHOLOGYAbout Our NewsletterInside Pathology is an newsletter published by the Chairman's Office to bring news and updates from inside the department's research and to become familiar with those leading it. It is our hope that those who read it will enjoy hearing about those new and familiar, and perhaps help in furthering our research. CONTENTS

|

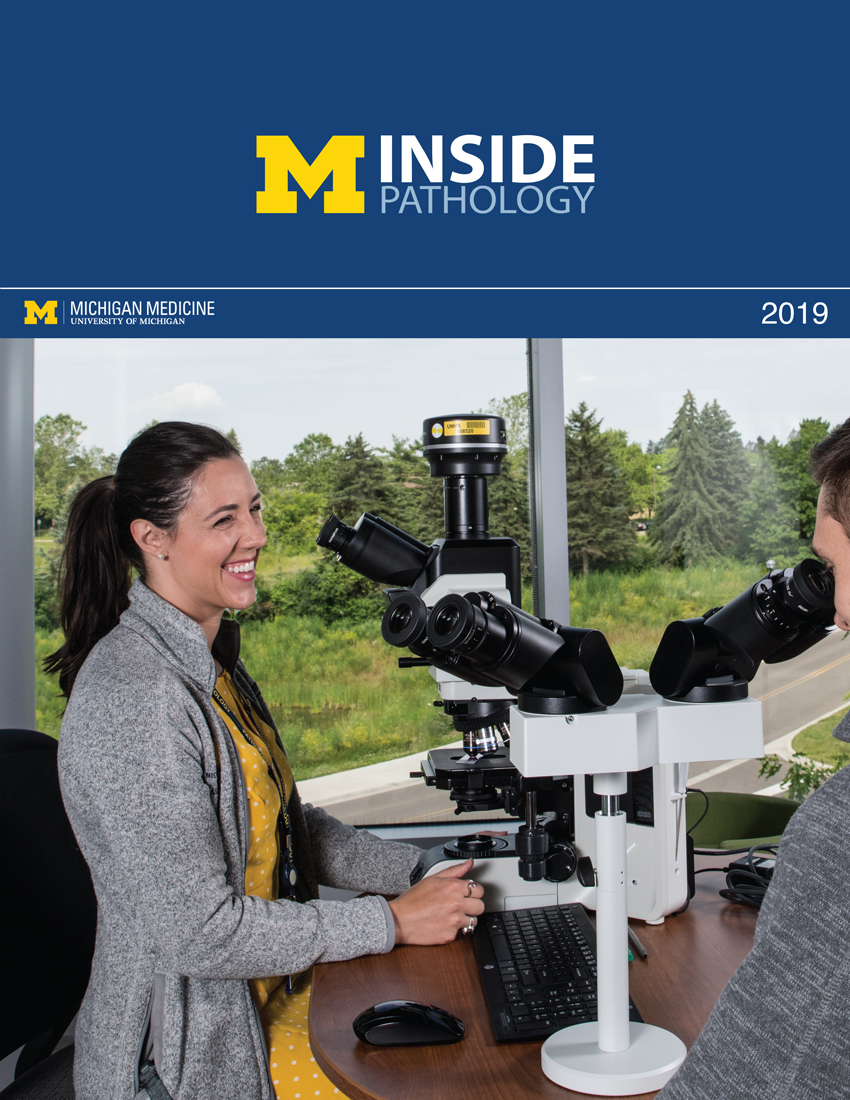

ON THE COVER

ON THE COVER

Residents Ashley Bradt (left) and William Perry work at a multi-headed scope in our new facility. 2019Department Chair |

newsletter

INSIDE PATHOLOGYAbout Our NewsletterInside Pathology is an newsletter published by the Chairman's Office to bring news and updates from inside the department's research and to become familiar with those leading it. It is our hope that those who read it will enjoy hearing about those new and familiar, and perhaps help in furthering our research. CONTENTS

|

ON THE COVER

ON THE COVER

Dr. Kristine Konopka (right) instructing residents while using a multi-headed microscope. 2020Department Chair |

newsletter

INSIDE PATHOLOGYAbout Our NewsletterInside Pathology is an newsletter published by the Chairman's Office to bring news and updates from inside the department's research and to become familiar with those leading it. It is our hope that those who read it will enjoy hearing about those new and familiar, and perhaps help in furthering our research. CONTENTS

|

ON THE COVER

ON THE COVER

Patient specimens poised for COVID-19 PCR testing. 2021Department Chair |

newsletter

INSIDE PATHOLOGYAbout Our NewsletterInside Pathology is an newsletter published by the Chairman's Office to bring news and updates from inside the department's research and to become familiar with those leading it. It is our hope that those who read it will enjoy hearing about those new and familiar, and perhaps help in furthering our research. CONTENTS

|

ON THE COVER

ON THE COVER

Dr. Pantanowitz demonstrates using machine learning in analyzing slides. 2022Department Chair |

newsletter

INSIDE PATHOLOGYAbout Our NewsletterInside Pathology is an newsletter published by the Chairman's Office to bring news and updates from inside the department's research and to become familiar with those leading it. It is our hope that those who read it will enjoy hearing about those new and familiar, and perhaps help in furthering our research. CONTENTS

|

ON THE COVER

ON THE COVER

(Left to Right) Drs. Angela Wu, Laura Lamps, and Maria Westerhoff. 2023Department Chair |

newsletter

INSIDE PATHOLOGYAbout Our NewsletterInside Pathology is an newsletter published by the Chairman's Office to bring news and updates from inside the department's research and to become familiar with those leading it. It is our hope that those who read it will enjoy hearing about those new and familiar, and perhaps help in furthering our research. CONTENTS

|

ON THE COVER

ON THE COVER

Illustration representing the various machines and processing used within our labs. 2024Department Chair |

newsletter

INSIDE PATHOLOGYAbout Our NewsletterInside Pathology is an newsletter published by the Chairman's Office to bring news and updates from inside the department's research and to become familiar with those leading it. It is our hope that those who read it will enjoy hearing about those new and familiar, and perhaps help in furthering our research. CONTENTS

|

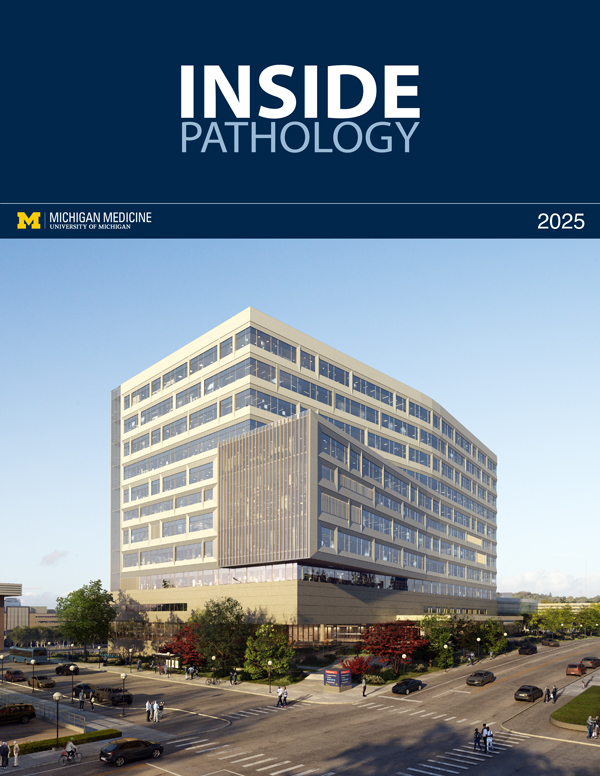

ON THE COVER

ON THE COVER

Rendering of the D. Dan and Betty Khn Health Care Pavilion. Credit: HOK 2025Department Chair |

newsletter

INSIDE PATHOLOGYAbout Our NewsletterInside Pathology is an newsletter published by the Chairman's Office to bring news and updates from inside the department's research and to become familiar with those leading it. It is our hope that those who read it will enjoy hearing about those new and familiar, and perhaps help in furthering our research. CONTENTS

|

MLabs, established in 1985, functions as a portal to provide pathologists, hospitals. and other reference laboratories access to the faculty, staff and laboratories of the University of Michigan Health System’s Department of Pathology. MLabs is a recognized leader for advanced molecular diagnostic testing, helpful consultants and exceptional customer service.