Our understanding of "Quality" in the Department of Pathology at Michigan Medicine may not be exactly what you’re expecting.

We have long used a variety of tools including Lean (or Toyota Production) principles, CAP checklists, and the Quality System Essentials as outlined by the Clinical Laboratory Standards Institute (CLSI) in operational quality assurance and quality improvement activities, with much success.

The Division of Quality and Health Improvement (DQHI) was established in late 2014, partly in support of these and other operational quality activities, providing additional expertise and resources in quality audits, root cause analyses, process improvement, accreditation, patient safety, and other activities. In addition, however, DQHI’s mission and vision include a large number of activities aimed squarely at changing the way pathology is practiced, and transforming the patient experience.

How are we doing this? By reimagining the role of pathology and laboratory medicine in the care of patients and continuously pushing the envelope of what’s possible; by directly involving patients and families in their care, practicing our brand of medicine with patients and families, not simply to and for them; by ensuring that we are the best possible stewards of our patients’ precious time, their unique diagnostic specimens, and the finite resources of the ever-changing healthcare system; by leading these innovations from the pathology platform, with its unique testing expertise and unparalleled understanding of pathophysiology.

To these ends, DQHI has partnered with stakeholders and experts within the Department, around the Michigan Medicine enterprise, in the broader University of Michigan community, and beyond, to undertake a number of important projects that you can learn about on this website.

Additional Resources:

A comprehensive Departmental Quality Plan ensures that the goals, organization, and expectations for operational quality activities are clearly defined and communicated to Departmental faculty and staff. The Quality Plan is also used to ensure accountability and engagement at all levels of the Department for activities and behaviors that drive quality outcomes and patient safety. Using the CLSI ‘s twelve Quality System Essentials as a foundation, the plan is intended to align daily work with Departmental priorities, detect and reduce errors and variability, and identify opportunities for improvement.

Ongoing internal audits ensure compliance with the Quality System Essentials as outlined in the Quality Plan and allow for the identification of vulnerabilities and remediation of issues before quality is affected.

The plan is reviewed on an annual basis to evaluate the continued effectiveness of the program elements and updated as necessitated. For the most current quality plan, click here Annual Quality Plan.

The Department of Pathology uses the Clinical and Laboratory Standards Institute (CLSI)’s Quality Management System as its comprehensive quality model for laboratory services. This system consists of twelve Quality System Essentials (QSE’s):

|

|

QSE Organization describes key leadership responsibilities that are integral to a laboratory’s success in achieving and maintaining a systematic approach to quality and meeting regulatory, accreditation, customer, and internal requirements.

QSE Customer Focus describes the laboratory’s identification of its customers and their expectations, and the need to design work to meet those expectations and any applicable requirements. It also describes methods to seek customer input to confirm expectations are continually being met.

QSE Facilities and Safety provides information about the laboratory’s physical environment and the maintenance and safety programs needed to support it.

People are the most valuable resource of the organization. QSE Personnel provides information about obtaining and retaining an adequate number of qualified, well-trained, and competent laboratory staff to perform and manage the activities of the laboratory.

QSE Purchasing and Inventory describes agreements that the laboratory has with entities it provides services to and entities from which it obtains products and services to ensure that specified requirements are consistently met.

QSE Equipment describes selection and installation of equipment, equipment maintenance and calibration, documentation of equipment-related problems, and record maintenance to ensure that equipment performs as expected for its intended use.

The QSE Process Management describes policies and processes for all work operations in the laboratory’s path of workflow. It involves all 12 QSE’s in some manner, because processes transform policies into action.

QSE Documents and Records describes the creation, management, and retention of policy, process, procedure, forms and template documents for the QSEs and path of workflow and records generated as a result of performing the activities in the laboratory’s Quality Management System.

The QSE Information Management provides guidance for managing internal and external data and information generated and entered into a paper-based or electronic recordkeeping system (e.g., patient demographics, examination results and reports, interpretations) and disseminated electronically or otherwise to users or other computer systems (e.g., verbal requests, printing, automatic faxing, e-mail, interfaces).

The purpose of an event management program is to capture and analyze nonconforming events (NCEs) to identify systemic problems and gain management’s commitment to removing the cause.

The QSE Assessments describes the use of external and internal monitoring and assessment to verify that laboratory processes meet requirements and to determine how well those processes are functioning.

The QSE Continual Improvement describes mechanisms for identifying opportunities for improvement and use of a defined strategy for CI. CI is critical to optimizing the effectiveness of the QMS and for sustaining quality.

The Michigan Quality System is based on principles pioneered by Toyota and refined in industry and healthcare institutions all over the world. These principles, collectively, are called lean, and the core aim is to maximize customer value and minimize waste. Lean thinking changes the focus of management from optimizing separate technologies, assets, and vertical departments to optimizing the flow of products and services through entire value streams that flow horizontally across technologies, assets, and departments to customers.

To accomplish the goal of maximizing value and minimizing waste, a number of tools have been developed to help you improve your processes. You can find those tools by clicking here.

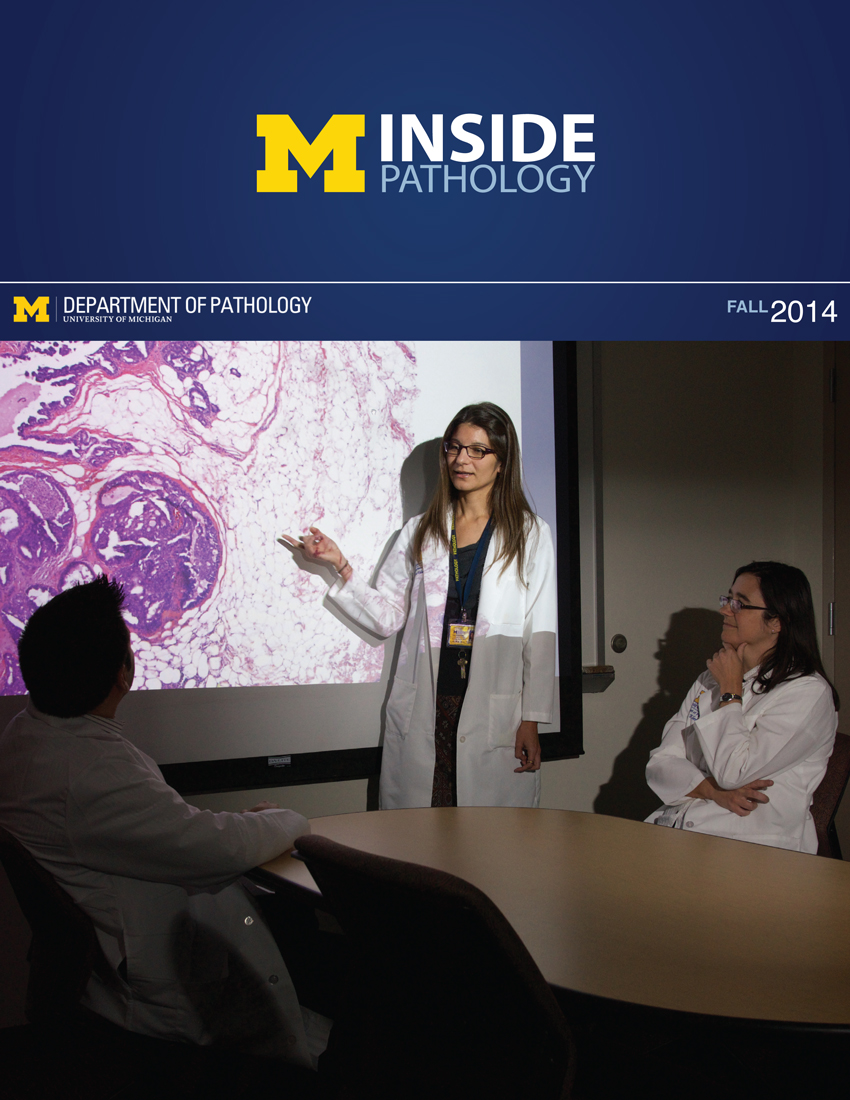

ON THE COVER

ON THE COVER

Breast team reviewing a patient's slide. (From left to right) Ghassan Allo, Fellow; Laura Walters, Clinical Lecturer; Celina Kleer, Professor. See Article 2014Department Chair |

newsletter

INSIDE PATHOLOGYAbout Our NewsletterInside Pathology is an newsletter published by the Chairman's Office to bring news and updates from inside the department's research and to become familiar with those leading it. It is our hope that those who read it will enjoy hearing about those new and familiar, and perhaps help in furthering our research. CONTENTS

|

ON THE COVER

ON THE COVER

Autopsy Technician draws blood while working in the Wayne County morgue. See Article 2016Department Chair |

newsletter

INSIDE PATHOLOGYAbout Our NewsletterInside Pathology is an newsletter published by the Chairman's Office to bring news and updates from inside the department's research and to become familiar with those leading it. It is our hope that those who read it will enjoy hearing about those new and familiar, and perhaps help in furthering our research. CONTENTS

|

ON THE COVER

ON THE COVER

Dr. Sriram Venneti, MD, PhD and Postdoctoral Fellow, Chan Chung, PhD investigate pediatric brain cancer. See Article 2017Department Chair |

newsletter

INSIDE PATHOLOGYAbout Our NewsletterInside Pathology is an newsletter published by the Chairman's Office to bring news and updates from inside the department's research and to become familiar with those leading it. It is our hope that those who read it will enjoy hearing about those new and familiar, and perhaps help in furthering our research. CONTENTS

|

ON THE COVER

ON THE COVER

Director of the Neuropathology Fellowship, Dr. Sandra Camelo-Piragua serves on the Patient and Family Advisory Council. 2018Department Chair |

newsletter

INSIDE PATHOLOGYAbout Our NewsletterInside Pathology is an newsletter published by the Chairman's Office to bring news and updates from inside the department's research and to become familiar with those leading it. It is our hope that those who read it will enjoy hearing about those new and familiar, and perhaps help in furthering our research. CONTENTS

|

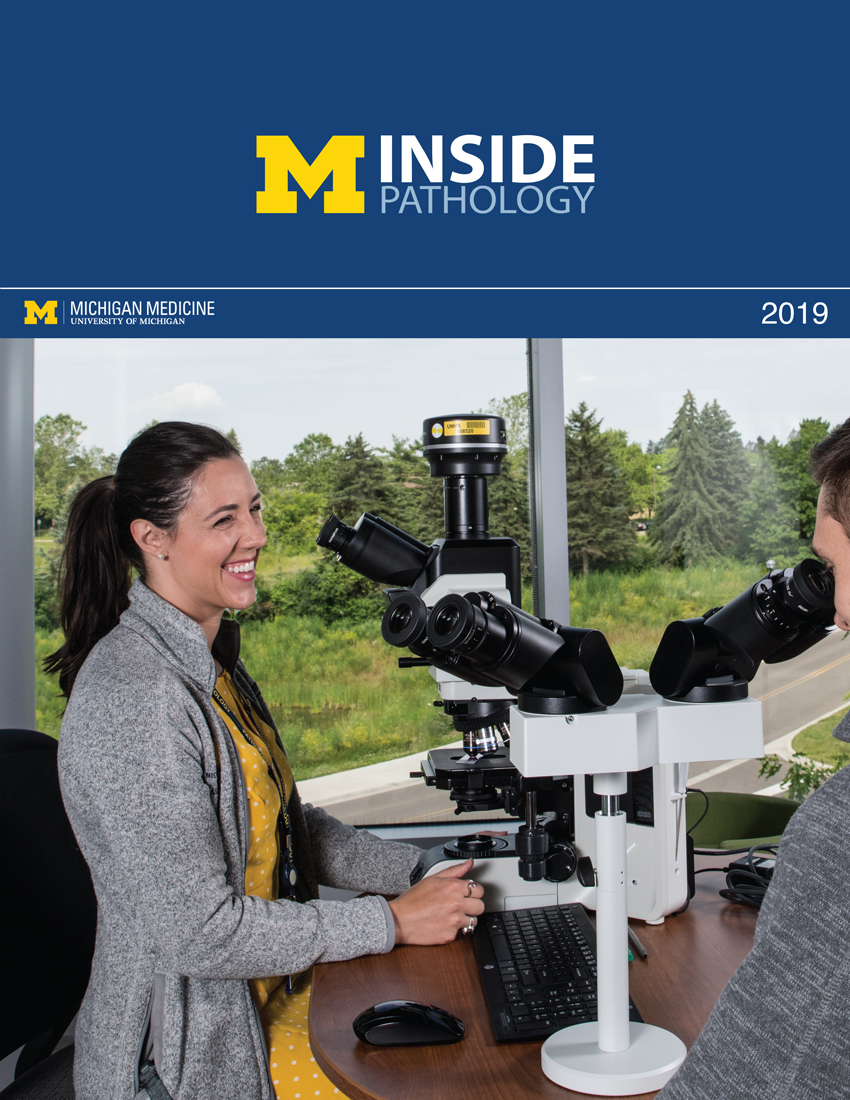

ON THE COVER

ON THE COVER

Residents Ashley Bradt (left) and William Perry work at a multi-headed scope in our new facility. 2019Department Chair |

newsletter

INSIDE PATHOLOGYAbout Our NewsletterInside Pathology is an newsletter published by the Chairman's Office to bring news and updates from inside the department's research and to become familiar with those leading it. It is our hope that those who read it will enjoy hearing about those new and familiar, and perhaps help in furthering our research. CONTENTS

|

ON THE COVER

ON THE COVER

Dr. Kristine Konopka (right) instructing residents while using a multi-headed microscope. 2020Department Chair |

newsletter

INSIDE PATHOLOGYAbout Our NewsletterInside Pathology is an newsletter published by the Chairman's Office to bring news and updates from inside the department's research and to become familiar with those leading it. It is our hope that those who read it will enjoy hearing about those new and familiar, and perhaps help in furthering our research. CONTENTS

|

ON THE COVER

ON THE COVER

Patient specimens poised for COVID-19 PCR testing. 2021Department Chair |

newsletter

INSIDE PATHOLOGYAbout Our NewsletterInside Pathology is an newsletter published by the Chairman's Office to bring news and updates from inside the department's research and to become familiar with those leading it. It is our hope that those who read it will enjoy hearing about those new and familiar, and perhaps help in furthering our research. CONTENTS

|

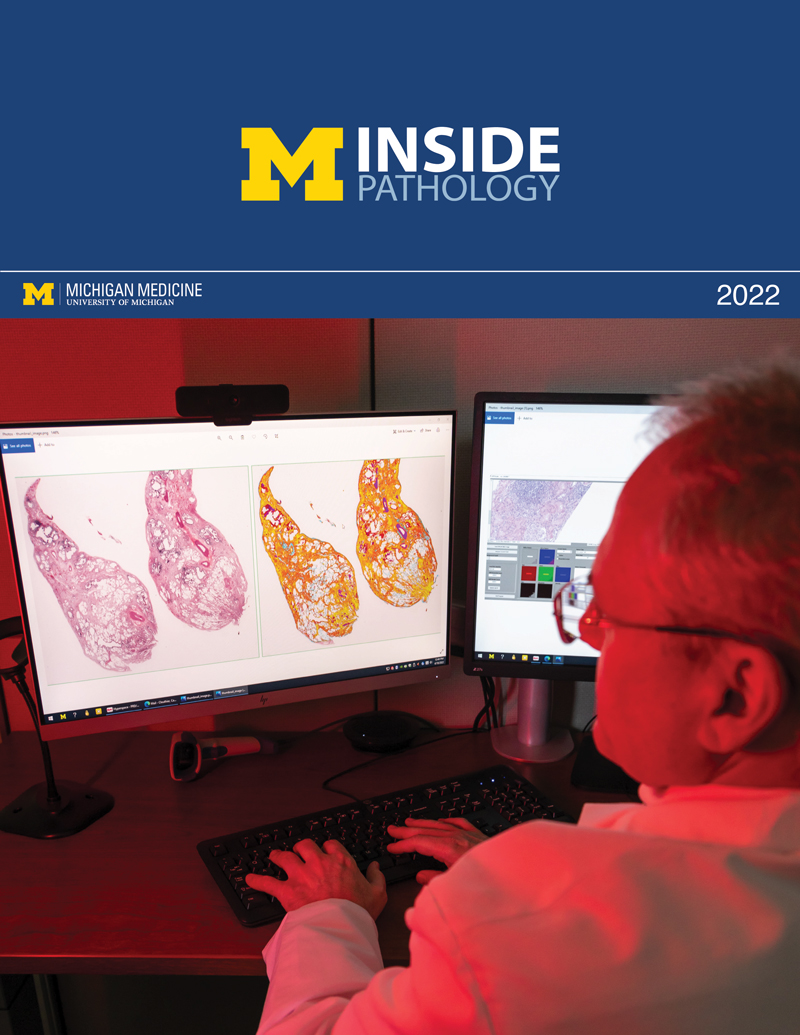

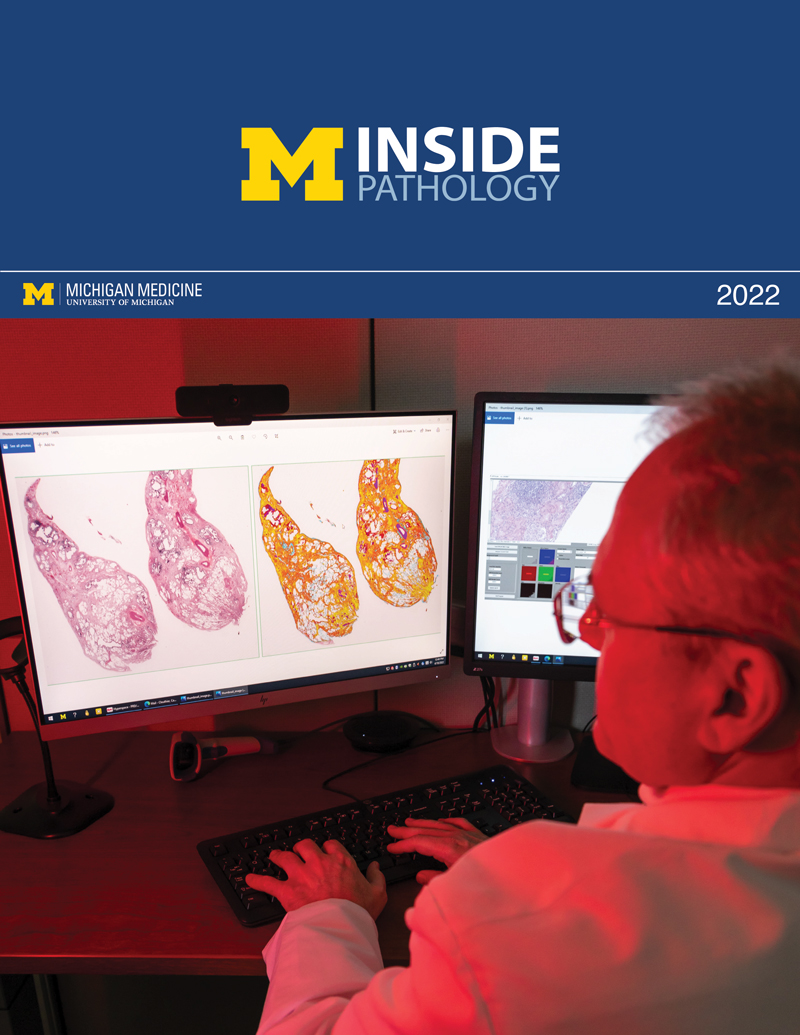

ON THE COVER

ON THE COVER

Dr. Pantanowitz demonstrates using machine learning in analyzing slides. 2022Department Chair |

newsletter

INSIDE PATHOLOGYAbout Our NewsletterInside Pathology is an newsletter published by the Chairman's Office to bring news and updates from inside the department's research and to become familiar with those leading it. It is our hope that those who read it will enjoy hearing about those new and familiar, and perhaps help in furthering our research. CONTENTS

|

ON THE COVER

ON THE COVER

(Left to Right) Drs. Angela Wu, Laura Lamps, and Maria Westerhoff. 2023Department Chair |

newsletter

INSIDE PATHOLOGYAbout Our NewsletterInside Pathology is an newsletter published by the Chairman's Office to bring news and updates from inside the department's research and to become familiar with those leading it. It is our hope that those who read it will enjoy hearing about those new and familiar, and perhaps help in furthering our research. CONTENTS

|

ON THE COVER

ON THE COVER

Illustration representing the various machines and processing used within our labs. 2024Department Chair |

newsletter

INSIDE PATHOLOGYAbout Our NewsletterInside Pathology is an newsletter published by the Chairman's Office to bring news and updates from inside the department's research and to become familiar with those leading it. It is our hope that those who read it will enjoy hearing about those new and familiar, and perhaps help in furthering our research. CONTENTS

|

ON THE COVER

ON THE COVER

Rendering of the D. Dan and Betty Khn Health Care Pavilion. Credit: HOK 2025Department Chair |

newsletter

INSIDE PATHOLOGYAbout Our NewsletterInside Pathology is an newsletter published by the Chairman's Office to bring news and updates from inside the department's research and to become familiar with those leading it. It is our hope that those who read it will enjoy hearing about those new and familiar, and perhaps help in furthering our research. CONTENTS

|

MLabs, established in 1985, functions as a portal to provide pathologists, hospitals. and other reference laboratories access to the faculty, staff and laboratories of the University of Michigan Health System’s Department of Pathology. MLabs is a recognized leader for advanced molecular diagnostic testing, helpful consultants and exceptional customer service.