|

Month |

QSE |

Audit Topic |

|

Jan |

QSE 11 Assessments |

Documentation of unscored/failure of Proficiency Testing review |

|

Feb |

QSE 4 Personnel

|

Laboratory Personnel Roster Audit & Blue Folder Audit |

|

QSE 8 Documents and Records |

Master Control Sign-off for Outstanding Procedures and Training

|

|

|

Mar |

QSE 8 Documents and Records |

Critical Value Audit |

|

Apr |

|

|

|

May |

QSE 5 Purchasing and Inventory |

Clinical Engineering (Bio-Med) stickers on equipment |

|

June |

QSE 7 Process Management |

IQCP documents complete (Quality Assessment Follow-up) |

|

July |

QSE 2 Customer Focus |

Customer service assessment performed (Lab Ambassador Committee) |

|

August |

QSE 10 Nonconforming Events Management |

Follow-up documentation on Patient Safety Reports (PSR) |

|

September |

QSE 3 Facilities and Safety |

Emergency Preparedness Plan procedure (COOP)

|

|

QSE 8 Documents and Records |

Critical Value Audit |

|

|

October |

QSE 6 Equipment

|

Manufacturer Reagent Insert process |

|

QSE 12 Continual Improvement |

Employee Engagement Efforts: New Employee Orientation |

|

|

November |

QSE 9 Information Management |

IT Downtime procedure |

|

December |

QSE 11 Assessments |

Follow-up on CAP citations |

|

QSE 1 Organization |

Organizational Charts available for sections of the lab and pathology administration |

|

| QSE 3 Facilities and Safety Audits – To be performed by Safety Committee Members | ||

|

January |

Facilities and Safety

|

Chemical Inventory Available Submitted |

|

Personal Protective Equipment worn per lab policy |

||

|

February |

Facilities and Safety

|

Annual Safety Audit |

|

March |

Facilities and Safety

|

Biohazard and other warning signs are on doors and refrigerators |

|

Spill kits are appropriate for lab, in-date (dated), and staff can locate them. |

||

|

April |

Facilities and Safety

|

Waste is labeled and disposed according to safety and recycling requirements |

|

Records of accidents are being maintained |

||

|

May |

Facilities and Safety

|

Storage - <18” from ceiling and not in halls or blocking egress No floor storage |

|

Lab prepared chemicals dated and labeled |

||

|

June |

Facilities and Safety |

Chemical Exposure monitoring is being performed if needed |

|

Staff can identify the new SDS & chemical labeling |

||

|

July |

Facilities and Safety

|

Safety Scavenger Hunt |

|

Ergonomics- |

||

|

August |

Facilities and Safety

|

Specimen transport |

|

Engineering Controls |

||

|

September |

Facilities and Safety |

Personal Protective Equipment worn per lab policy |

|

Facilities and Safety |

Check glassware for cracks and chips |

|

|

October |

Facilities and Safety |

Eyewash and Showers are operable; staff know how to use them |

|

Inoperable equipment is tagged and unplugged |

||

|

November |

Facilities and Safety |

Compressed gas tanks are chained |

|

Facilities and Safety |

Lab specific procedures in Master Control |

|

|

December |

Facilities and Safety |

Fire Drill Participation Report Completed |

|

SDS Sheets are up to date |

||

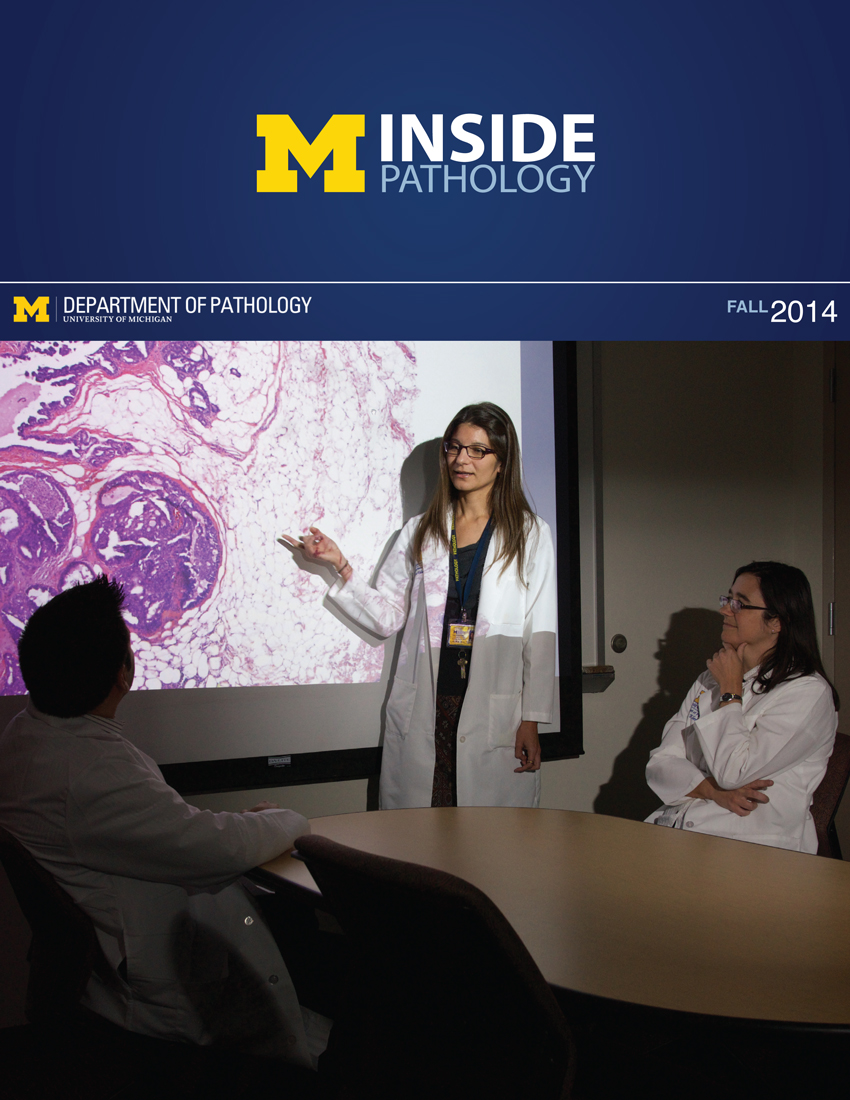

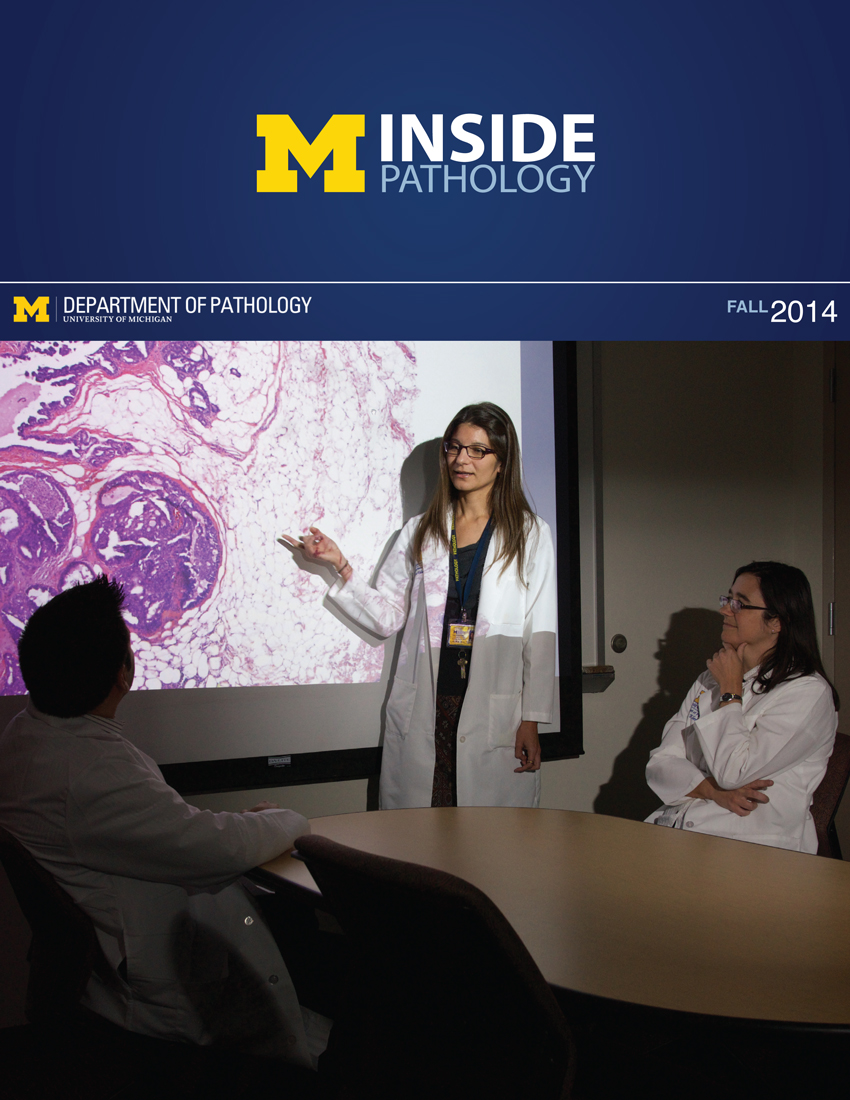

ON THE COVER

ON THE COVER

Breast team reviewing a patient's slide. (From left to right) Ghassan Allo, Fellow; Laura Walters, Clinical Lecturer; Celina Kleer, Professor. See Article 2014Department Chair |

newsletter

INSIDE PATHOLOGYAbout Our NewsletterInside Pathology is an newsletter published by the Chairman's Office to bring news and updates from inside the department's research and to become familiar with those leading it. It is our hope that those who read it will enjoy hearing about those new and familiar, and perhaps help in furthering our research. CONTENTS

|

ON THE COVER

ON THE COVER

Autopsy Technician draws blood while working in the Wayne County morgue. See Article 2016Department Chair |

newsletter

INSIDE PATHOLOGYAbout Our NewsletterInside Pathology is an newsletter published by the Chairman's Office to bring news and updates from inside the department's research and to become familiar with those leading it. It is our hope that those who read it will enjoy hearing about those new and familiar, and perhaps help in furthering our research. CONTENTS

|

ON THE COVER

ON THE COVER

Dr. Sriram Venneti, MD, PhD and Postdoctoral Fellow, Chan Chung, PhD investigate pediatric brain cancer. See Article 2017Department Chair |

newsletter

INSIDE PATHOLOGYAbout Our NewsletterInside Pathology is an newsletter published by the Chairman's Office to bring news and updates from inside the department's research and to become familiar with those leading it. It is our hope that those who read it will enjoy hearing about those new and familiar, and perhaps help in furthering our research. CONTENTS

|

ON THE COVER

ON THE COVER

Director of the Neuropathology Fellowship, Dr. Sandra Camelo-Piragua serves on the Patient and Family Advisory Council. 2018Department Chair |

newsletter

INSIDE PATHOLOGYAbout Our NewsletterInside Pathology is an newsletter published by the Chairman's Office to bring news and updates from inside the department's research and to become familiar with those leading it. It is our hope that those who read it will enjoy hearing about those new and familiar, and perhaps help in furthering our research. CONTENTS

|

ON THE COVER

ON THE COVER

Residents Ashley Bradt (left) and William Perry work at a multi-headed scope in our new facility. 2019Department Chair |

newsletter

INSIDE PATHOLOGYAbout Our NewsletterInside Pathology is an newsletter published by the Chairman's Office to bring news and updates from inside the department's research and to become familiar with those leading it. It is our hope that those who read it will enjoy hearing about those new and familiar, and perhaps help in furthering our research. CONTENTS

|

ON THE COVER

ON THE COVER

Dr. Kristine Konopka (right) instructing residents while using a multi-headed microscope. 2020Department Chair |

newsletter

INSIDE PATHOLOGYAbout Our NewsletterInside Pathology is an newsletter published by the Chairman's Office to bring news and updates from inside the department's research and to become familiar with those leading it. It is our hope that those who read it will enjoy hearing about those new and familiar, and perhaps help in furthering our research. CONTENTS

|

ON THE COVER

ON THE COVER

Patient specimens poised for COVID-19 PCR testing. 2021Department Chair |

newsletter

INSIDE PATHOLOGYAbout Our NewsletterInside Pathology is an newsletter published by the Chairman's Office to bring news and updates from inside the department's research and to become familiar with those leading it. It is our hope that those who read it will enjoy hearing about those new and familiar, and perhaps help in furthering our research. CONTENTS

|

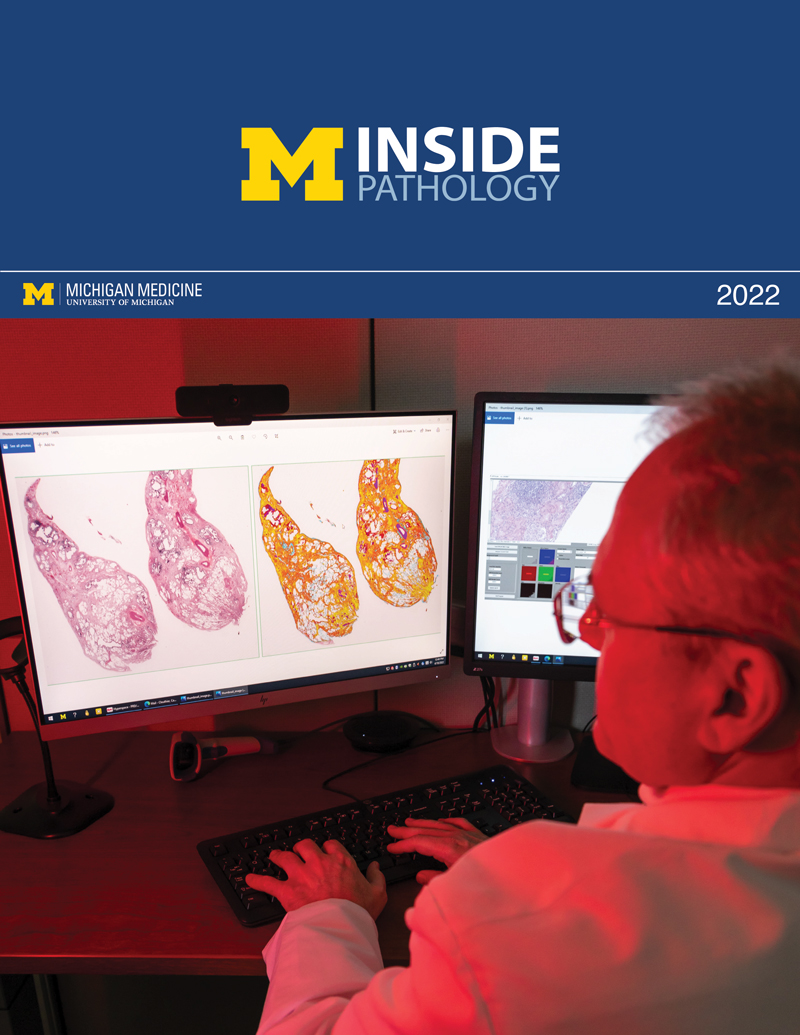

ON THE COVER

ON THE COVER

Dr. Pantanowitz demonstrates using machine learning in analyzing slides. 2022Department Chair |

newsletter

INSIDE PATHOLOGYAbout Our NewsletterInside Pathology is an newsletter published by the Chairman's Office to bring news and updates from inside the department's research and to become familiar with those leading it. It is our hope that those who read it will enjoy hearing about those new and familiar, and perhaps help in furthering our research. CONTENTS

|

ON THE COVER

ON THE COVER

(Left to Right) Drs. Angela Wu, Laura Lamps, and Maria Westerhoff. 2023Department Chair |

newsletter

INSIDE PATHOLOGYAbout Our NewsletterInside Pathology is an newsletter published by the Chairman's Office to bring news and updates from inside the department's research and to become familiar with those leading it. It is our hope that those who read it will enjoy hearing about those new and familiar, and perhaps help in furthering our research. CONTENTS

|

ON THE COVER

ON THE COVER

Illustration representing the various machines and processing used within our labs. 2024Department Chair |

newsletter

INSIDE PATHOLOGYAbout Our NewsletterInside Pathology is an newsletter published by the Chairman's Office to bring news and updates from inside the department's research and to become familiar with those leading it. It is our hope that those who read it will enjoy hearing about those new and familiar, and perhaps help in furthering our research. CONTENTS

|

MLabs, established in 1985, functions as a portal to provide pathologists, hospitals. and other reference laboratories access to the faculty, staff and laboratories of the University of Michigan Health System’s Department of Pathology. MLabs is a recognized leader for advanced molecular diagnostic testing, helpful consultants and exceptional customer service.